Mechanical Design of a Cabinet

Biomass Dryer Design

Client – Agricultural Equipment Supplier

Capabilities Demonstrated

- Rugged design for reliable operation within an Ag environment

- Human factors / user interface design

- SWaP (Size, Weight and Power) analysis and design

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- 3D mechanical design and simulation with SOLIDWORKS

Challenge

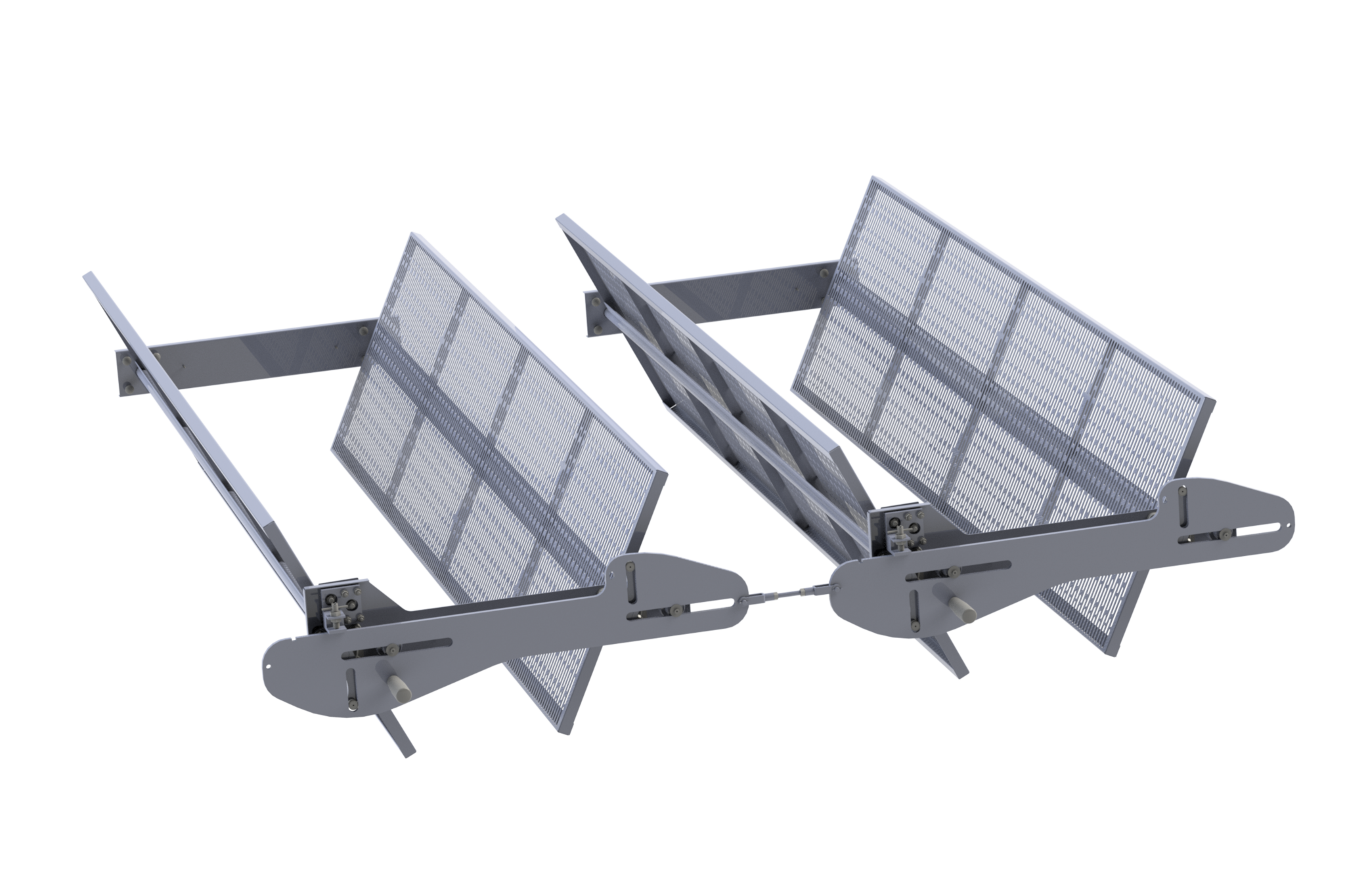

AppliedLogix was tasked with developing a customer-scalable Biomass Dryer Cabinet that could be readily (re)configured to meet each customer’s unique requirements. The core concept was based on developing vertically stackable assemblies that would be supplied to the end customer via a complete set of drawings and instructions. Further, the stackable units needed to be constructed from readily available building materials.

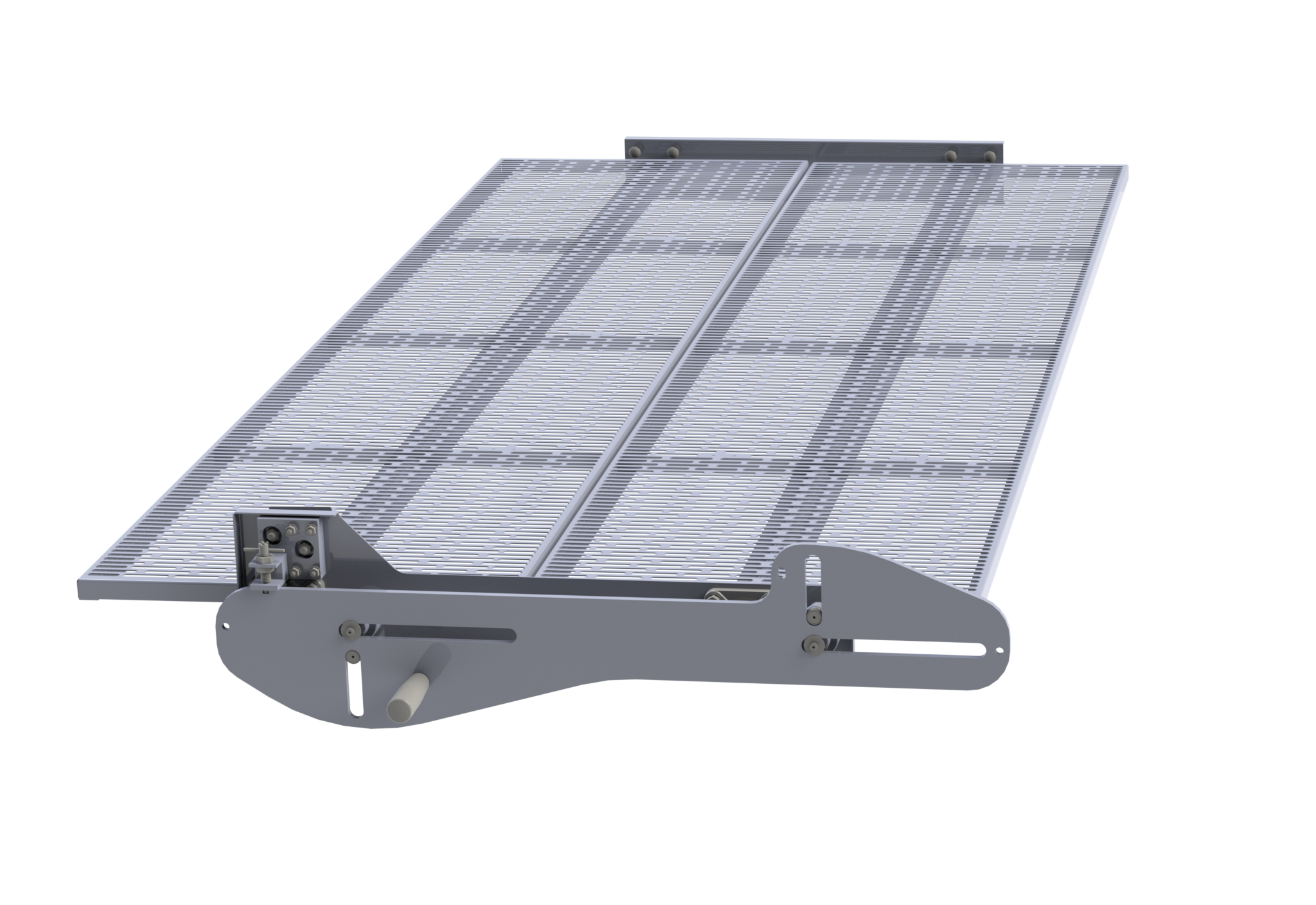

The stackable assemblies were required to support and convey wet biomass while simultaneously allowing sustained air flow through the assembly (to dry the material). As the biomass material is dried it is progressively conveyed to a lower level of the stacked assembly, thereby enabling additional “raw” biomass to be added at the top.

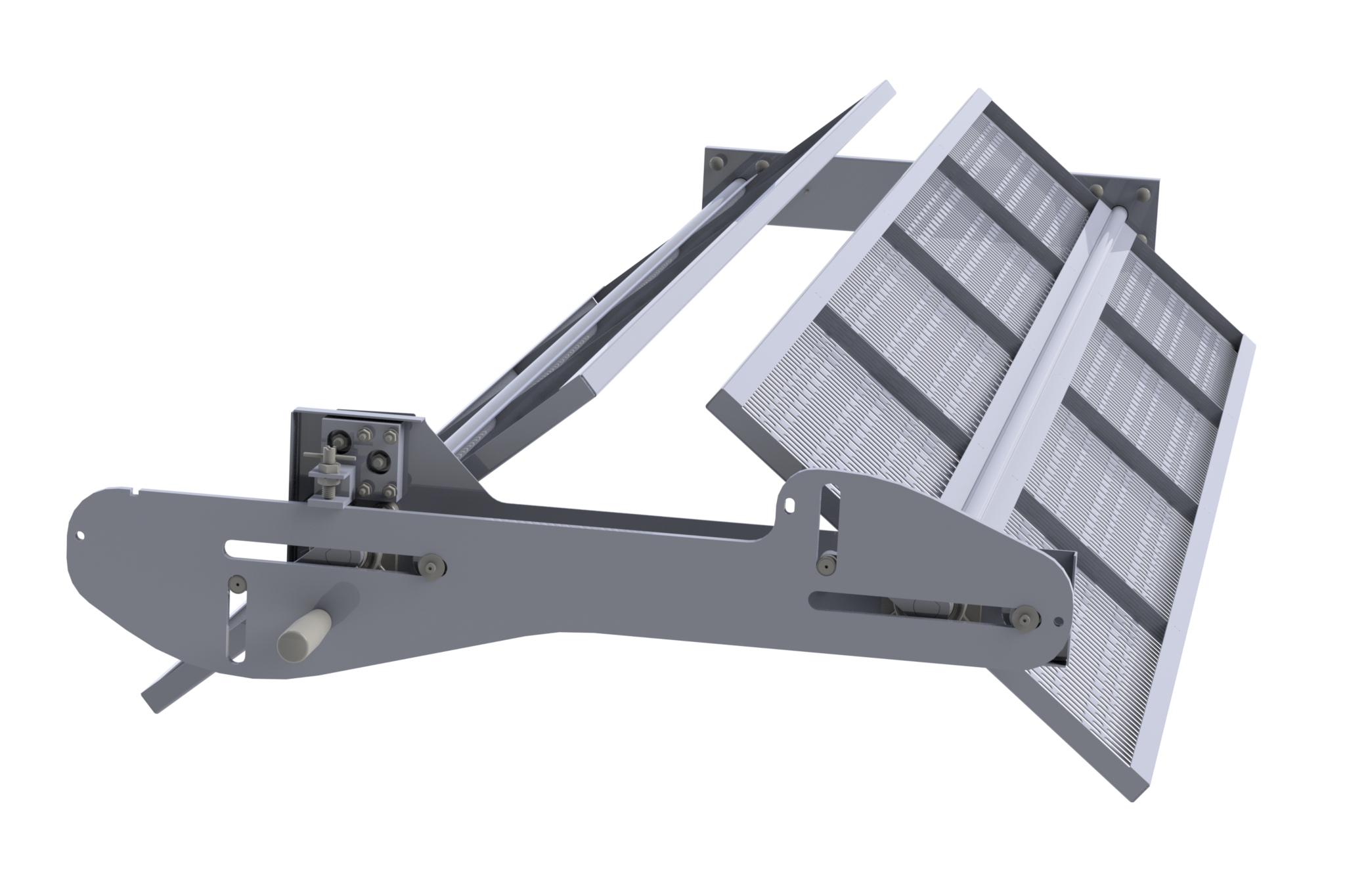

Conveying the biomass material between the stacked assemblies proved to be quite challenging. The mechanism needed to be both simple and reliable. We developed a unique design that balanced and controlled the counter-rotation of the assembly floor doors using a single linear motion (in both manual and semiautomated configurations) while preventing self-actuation during loading.

Additionally, the overall mechanism was required to be:

- low-cost,

- easy to assemble,

- and operate reliably in a dusty environment.

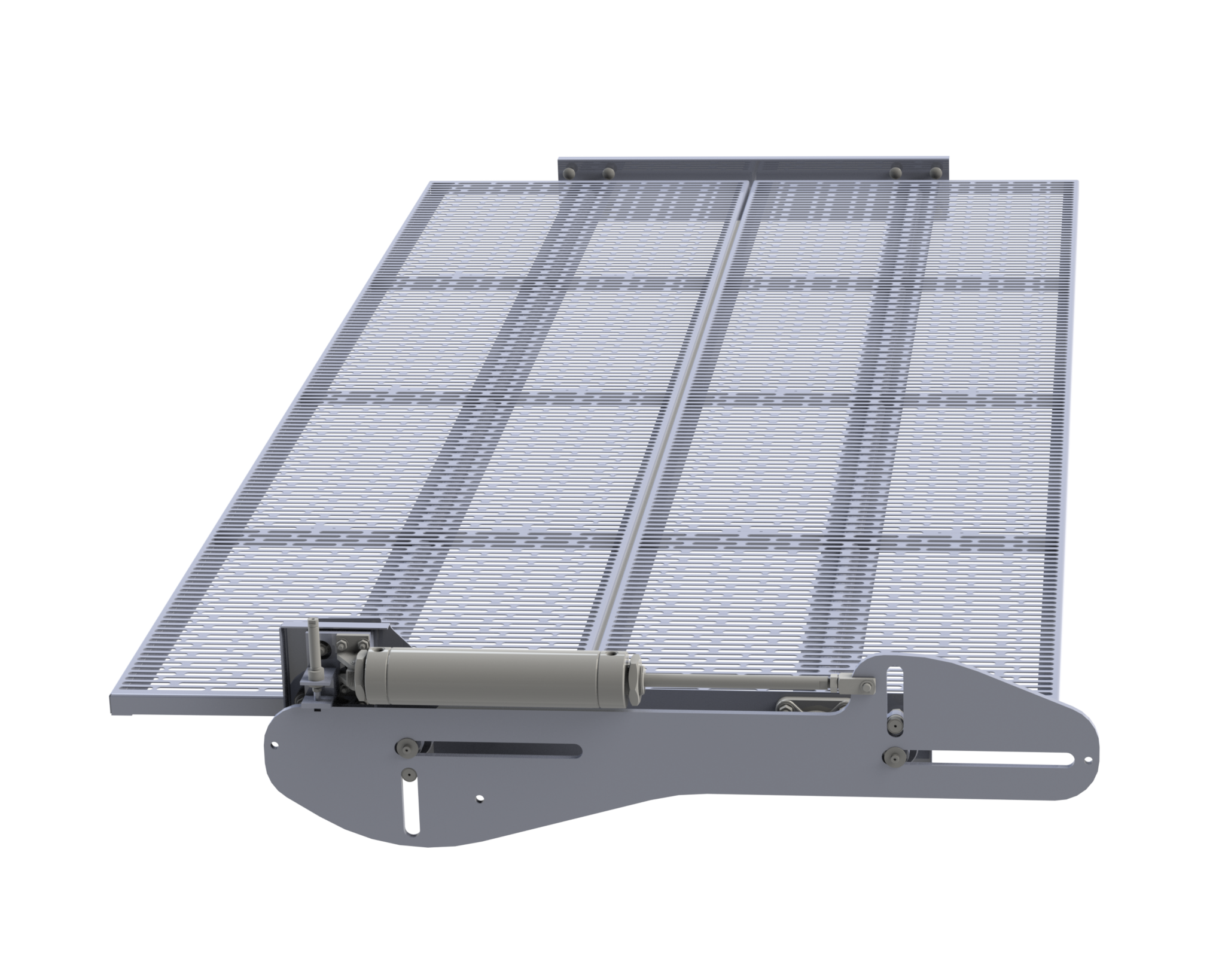

The standard configuration was based on manual actuation of the stackable unit floor mechanisms with a planned upgrade kit for the installation of pneumatic actuators and valves.

Solution

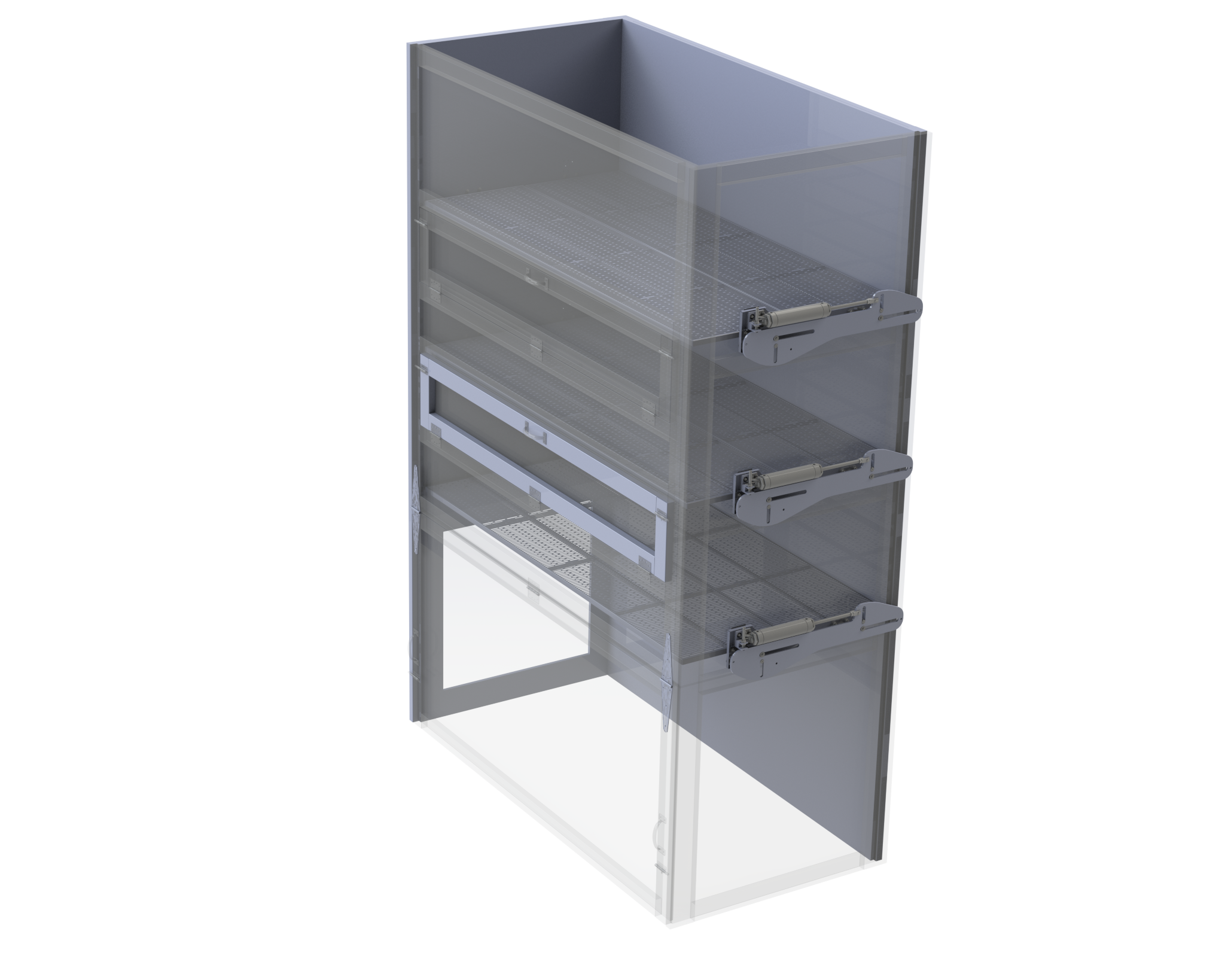

The standard dryer configuration incorporated three vertically stacked assemblies with top-loading. The bottom unit included a dryer fan to blow air up through the stacked assemblies. Each stacked unit includes an access door on the side of the cabinet for leveling of the biomass. The bottom unit dumps into a removable bin that can be transferred to the next process (into a bailing machine for example).

The final cabinet dimensions were based on an overarching requirement to simplify the construction using standard building materials. Once the overall dimensions were nailed-down, the range of motion and the mechanisms that operated the doors within the stacked assemblies were developed and optimized.

SolidWorks 3D CAE tools were utilized to develop the initial mechanism concepts which were then optimized via iterative design reviews and the concept-down selection process. The CAE tools enabled the efficient capture of the mechanism and accurately modeled the motion and clearances of the various components.

The resulting mechanism was designed in two configurations:

- manual actuation, or

- pneumatic actuation,

enabling the end customer to set the system up to suit their needs.

Also, the stackable assembly units were designed to be coupled in parallel (using turnbuckles between the cam plates), thereby enabling the system to be readily scaled-up for processing larger volumes of biomass.

Assembly instructions, cut lists, and bills of materials were generated to aid the end user during their building process.

Benefits

- Precise motion control that translates approximately 7” of motion into around 165 degrees of rotation on the doors on the floor sub-assembly.

- Highly flexible and configurable design that can be customized to meet the needs of the end customer in a manual or semi-automated configuration.

- Easily manufactured and serviced